Iprofayile yekhampani

I-YPAK PACKAGING GROUP yasekwa ngo-2011 yaza yasekwa neenkampani ezi-3 ezisekwe eHongkong, eDongguan naseFoshan. Siye saba ngomnye wabavelisi abakhulu beengxowa zekofu eTshayina. Sisebenzisa iivalvu zeWIPF ezisemgangathweni ophezulu ezivela eSwitzerland ukugcina ikofu yakho itsha.

Silandela umgaqo-nkqubo wokuvalwa kweplastiki omiselwe kumazwe amaninzi ahlukeneyo, siye senza uphando saza saphuhlisa iingxowa zokupakisha ezizinzileyo, ezifana neengxowa ezinokuphinda zisetyenziswe nezinokuxovwa.

Akukho buninzi buncinci, akukho mibala ifunekayo ngenkonzo yethu ye-HP 25K INDIGO DIGITAL PRINTING.

Injongo yethu kukukhusela okusingqongileyo ngokusebenzisa iipakethe zethu zokutya ezilungele indalo.

Wamkelekile ukuba undwendwele i-YPAK.

Imbali Yethu

2012

NgoMeyi 2012, umgca wokuqala opheleleyo wokuvelisa ukupakisha oguquguqukayo waveliswa.

2016

NgoMatshi 2016, saqala ukuvelisa iingxowa ezisezantsi ezisicaba.

2017

Ngo-Agasti 2017, umgca wesibini wemveliso wasekwa.

2018

Ngo-Epreli 2018, kusetyenziswa ubuchwepheshe be-composite obungenazinyibilikisi.

2020

NgoJuni ka-2020, kwaqaliswa inkqubo yokulungisa i-inki ezenzekelayo.

2020

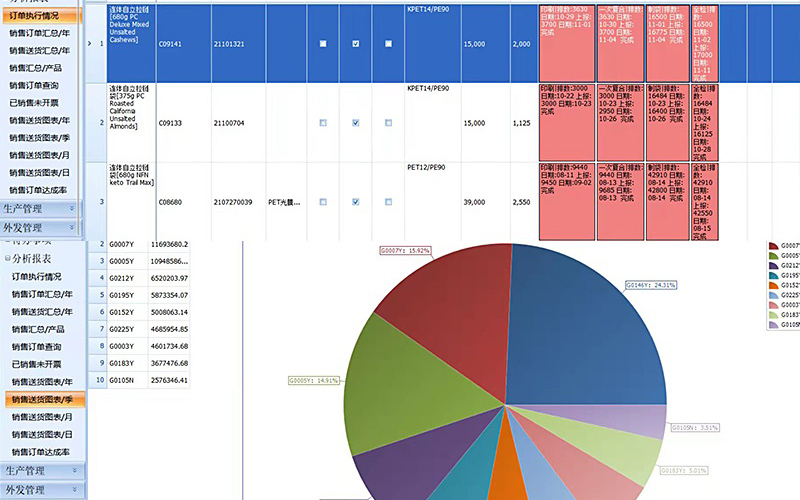

NgoJulayi 2020, inkqubo yemveliso ye-ERP yaziswa.

2021

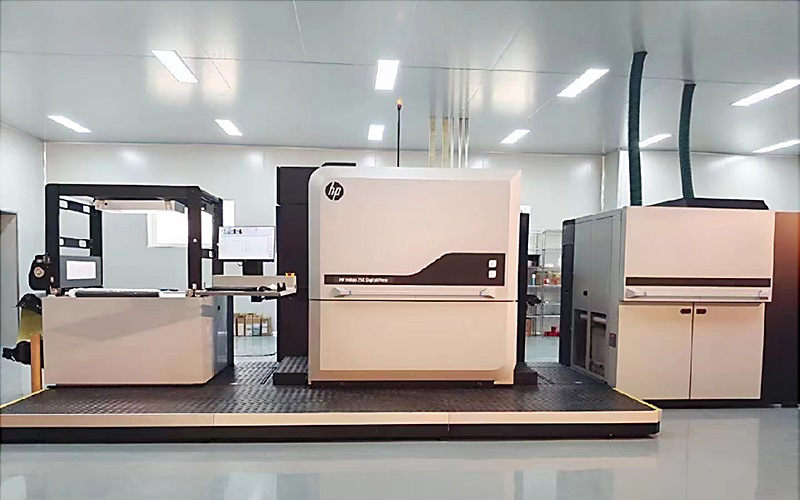

Ngo-Okthobha ka-2021, kwaveliswa umatshini wokuprinta wedijithali we-HP INDIGO 25K.

Ukuprinta iRotogravure, okwaziwa ngokuba kukuprinta igravure, yindlela ethandwayo kushishino lokuprinta kwaye ineenzuzo ezininzi. Le ndlela yokuprinta isetyenziswa kakhulu kwiingxowa zokupakisha eziguquguqukayo, iingxowa zokupakisha ukutya, iingxowa zekofu, njl.njl. kwaye ifanelekile kushishino lokupakisha.

Enye yezona nzuzo zibalaseleyo zokuprinta i-rotogravure kukumgangatho wayo ogqwesileyo womfanekiso. Inkqubo yokuprinta ibandakanya ukukrola umfanekiso kwisilinda, uze emva koko udluliselwe kwizinto ezifunwayo. Oku kwenza ukuba imifanekiso enesisombululo esiphezulu neneenkcukacha ziprintwe kwiingxowa, nto leyo ebonisa uyilo kunye nolwazi lwemveliso ngokuchanekileyo.

Ukongeza kumgangatho womfanekiso, ukuprinta igravure kukwabonelela ngokuveliswa kombala okugqwesileyo. Iirola zokukrola zivumela ukusetyenziswa kweinki ngokuthe ngqo nangokuchanekileyo kwizinto ezenziwe ngazo. Oku kubangela imibala eqaqambileyo necacileyo enceda iimveliso zibonakale kwiishelufu zeevenkile kwaye zenze zibonakale ngakumbi kubathengi.

Enye inzuzo yokuprinta i-rotogravure kukuba iyakwazi ukuguquguquka. Ingasetyenziswa kwizinto ezahlukeneyo kuquka iintlobo ezahlukeneyo zeplastiki, iifilimu kunye namaphepha. Oku kuzenza zilungele iingxowa zokupakisha eziguquguqukayo njengoko kufuneka zikwazi ukumelana neemeko ezahlukeneyo zokusingqongileyo ngelixa zibonelela ngokhuseleko olusebenzayo kwiimpahla ezingaphakathi. Nokuba ziingxowa zokupakisha ukutya, iingxowa zekofu okanye naluphi na olunye uhlobo lokupakisha oluguquguqukayo, ukuprinta i-rotogravure kunokuhlengahlengiswa ngokulula kwiimfuno ezithile zemveliso nganye.

Ngokuphathelele ukusebenza kakuhle, i-rotogravure igqwesile kwimveliso ephezulu. Isantya sayo sokuprinta sikhawuleza, kwaye inani elikhulu leengxowa zokupakisha linokwenziwa ngexesha elifutshane. Oku kuluncedo ngakumbi kumashishini afuna inani elikhulu leengxowa ukuze ahlangabezane neemfuno zobonelelo. Ukuprinta i-gravure kuqinisekisa ukuba iimveliso zinokupakishwa kwaye zihanjiswe ngexesha elifanelekileyo, kunceda iinkampani ukuhlangabezana nolindelo lwabathengi kunye nokugcina ithuba lokukhuphisana kwimarike.

Ukongeza, iingxowa zokuprinta zegravure ziqinile kakhulu. Iinki ifakwa nzulu kwizinto, nto leyo eyenza ikhonkco eliqinileyo elimelana nokunyamalala, ukukrweleka kunye nokonakala kokufuma. Oku kuqinisekisa ukuba isikhwama sinokumelana nokuphathwa, ukuthunyelwa kunye nokugcinwa ngaphandle kokuphazamisa ukukhangeleka kwayo. Abathengi banokuthemba ukuba iimveliso zabo ziya kukhuselwa kakuhle kwaye zigcine inkangeleko yazo yomgangatho ophezulu kulo lonke uthotho lokubonelela.

Ukuqukumbela, ukuprinta i-gravure kuneenzuzo ezininzi, nto leyo eyenza ukuba ibe lukhetho oluhle kakhulu kwiingxowa zokupakisha eziguquguqukayo, iingxowa zokupakisha ukutya kunye neengxowa zekofu. Umgangatho wayo ogqwesileyo womfanekiso, ukuveliswa kombala, ukuguquguquka nokusebenza kakuhle kwenza kube yindlela ekhethwayo kumashishini akwishishini lokupakisha. Ukongeza, ukuqina okunikezelwa ziingxowa ze-gravure kuqinisekisa ukuba iimveliso zihlala zibukeka kwaye zikhuselekile kwimveliso ukuya ekusetyenzisweni. Ngenxa yemfuno ekhulayo yezisombululo zokupakisha ezisemgangathweni ophezulu, ukuprinta i-gravure kuye kwavela njengokhetho oluthembekileyo nolusebenzayo kumashishini afuna ukuphucula uyilo lokupakisha kunye nokukhusela iimveliso.

I-HP INDIGO 25K DIGITAL PRESS

Kwihlabathi elihlala litshintsha lokupakisha, amashishini ahlala efuna iindlela zokugqama nokushiya umbono ohlala uhleli kubathengi. Ngenxa yokukhula kwemfuno yokupakisha eyenzelwe wena kwaye itsala amehlo, ukuprinta ngedijithali kuye kwaba yinto etshintsha umdlalo kwishishini. Namhlanje siza kuxoxa ngeenzuzo zokuprinta ngedijithali kwiingxowa zokupakisha eziguquguqukayo ezifana neengxowa zokupakisha zekofu kunye nokutya.

Kwihlabathi elihlala litshintsha lokupakisha, amashishini ahlala efuna iindlela zokugqama nokushiya umbono ohlala uhleli kubathengi. Ngenxa yokukhula kwemfuno yokupakisha eyenzelwe wena kwaye itsala amehlo, ukuprinta ngedijithali kuye kwaba yinto etshintsha umdlalo kwishishini. Namhlanje siza kuxoxa ngeenzuzo zokuprinta ngedijithali kwiingxowa zokupakisha eziguquguqukayo ezifana neengxowa zokupakisha zekofu kunye nokutya.

Enye yeenzuzo ezibalulekileyo zeHP Indigo 25K Digital Press, kukukwazi kwayo ukubonelela ngeeprinti ezikumgangatho ophezulu, ezikhanyayo nezineenkcukacha. Oku kuphumela ekupakishweni okumangalisayo okutsala ingqalelo yomthengi ngokulula. Nokuba yimizobo entsonkothileyo, imibala eqaqambileyo okanye imifanekiso efana nemifanekiso, ukuprinta kwedijithali kuqinisekisa ukuba yonke into ebhegini iyaphila. Eli nqanaba lomgangatho linceda imveliso ivele kwiishelufu zevenkile kwaye ibambe umdla wabathengi abanokubakho ngoko nangoko.

Ukongeza, ukuprinta ngedijithali kunika ukuguquguquka okungenakuthelekiswa nanto. Ngokungafaniyo neendlela zokuprinta zemveli, ukuprinta ngedijithali kunika amashishini amandla okuprinta iibhetshi ezincinci kunye nokutshintsha uyilo nangaliphi na ixesha, naphi na. Le nzuzo iluncedo ngakumbi kumashishini amancinci okanye amashishini afuna ukuphinda atshintshe uphawu lwawo ngamanye amaxesha. Ukusebenzisa ukuprinta ngedijithali, akukho mfuneko yokuprinta iingxowa zokupakisha ngeebhetshi, kunciphisa umngcipheko wokuchitha izixhobo ngenxa yobuninzi bempahla. Le ndlela ingabizi kakhulu ivumela amashishini ukuba agcine izisombululo zokupakisha eziguquguqukayo neziphendulayo ezizivumelanisa ngokulula neendlela zemarike kunye nezinto ezikhethwa ngabathengi.

Ukongeza ekuguquguqukeni, ukuprinta ngedijithali kukwabonelela ngamaxesha okutshintsha ngokukhawuleza xa kuthelekiswa neendlela zokuprinta zendabuko. Nge-HP Indigo 25K Digital Press, amashishini anokunciphisa kakhulu ixesha elithathwayo ukusuka kuyilo lokupakisha ukuya kwimveliso yokugqibela. Olu tshintsho lukhawulezileyo lubalulekile kumashishini asebenza kwiimarike ezikhawulezayo apho ixesha libaluleke kakhulu. Ukuprinta ngedijithali kwenza amashishini akwazi ukuphendula ngokukhawuleza kwiimfuno zemarike, aqalise iimveliso ezintsha ngokukhawuleza, kwaye enze utshintsho ngexesha langempela, eqinisekisa ukuba ahlala phambili kukhuphiswano kwaye andise amandla okuthengisa.

Ukongeza, ukuprintwa kwedijithali kweengxowa zokupakisha eziguquguqukayo kunobuhlobo nokusingqongileyo. Iindlela zokuprinta zemveli zihlala ziquka ukusetyenziswa kweekhemikhali eziyingozi kunye nenkunkuma eninzi. Nangona kunjalo, ukuprintwa kwedijithali kunciphisa kakhulu ezi ziphumo zimbi. Kufuna iikhemikhali ezimbalwa kwaye kuvelisa inkunkuma encinci, kunceda amashishini ukunciphisa umngcipheko wekhabhoni yawo kwaye anegalelo kwizenzo ezizinzileyo.

I-HP Indigo 25K Digital Press yenzelwe ukupakisha okuguquguqukayo, ukuqinisekisa ukunamathela okuhle kwe-inki kunye nokuqina kwayo. Oku kuthetha ukuba ukushicilela kwiingxowa zekofu, iingxowa zokutya kunye nezinye izisombululo zokupakisha eziguquguqukayo kuyamelana nokufiphala, ukudaya kunye nokonakala komswakama. Ukushicilela okusemgangathweni ophezulu kunye nokuqina okuhlala ixesha elide kwakha ukuthembana kunye nokuthembeka kubathengi, kubaqinisekisa ngobutsha kunye nomgangatho wemveliso.

Ngamafutshane, ngetekhnoloji yanamhlanje iHP Indigo 25K Digital Press, inika iingenelo ezininzi kwiingxowa zokupakisha eziguquguqukayo. Ukuprinta okusemgangathweni ophezulu, ukuguquguquka, utshintsho olukhawulezileyo kunye nokuzinza kokusingqongileyo kwenza ukuprinta kwedijithali kube lukhetho lokuqala kumashishini afuna ukwenza ukupakisha okunomtsalane. Ngokusebenzisa ukuprinta kwedijithali, amashishini anokuhlala efanelekileyo, aqhelane nokuguquguquka kwemarike, kwaye ekugqibeleni andise ukuqatshelwa kweempawu kunye nokuthengiswa. Kutheni ke wamkele ukupakishwa okuqhelekileyo xa ukuprinta kwedijithali kunokuguqula imveliso yakho ibe yinto engaqhelekanga?

Iimashini Zokugquma Ezingenasinyibilikisi

Kwishishini lokutya neziselo, ukupakisha kudlala indima ebalulekileyo ekuqinisekiseni umgangatho, ukhuseleko kunye nobutsha beemveliso ezithunyelwa kubathengi. Kwiminyaka yakutshanje, ukupakisha okuguquguqukayo kuye kwathandwa ngenxa yokuguquguquka kwayo, ixabiso eliphantsi, kunye nobuhlobo nokusingqongileyo. Kule shishini, ii-laminators ezingenazinyibilikisi ziye zatshintsha umdlalo, zatshintsha indlela ukupakisha ukutya, kuquka ukupakisha ikofu, okwenziwa ngayo. Kwi-YPAK, sizingca ngokubonelela ngee-laminators ezingenazinyibilikisi zanamhlanje ukuze ziprinte iingxowa zakho zokupakisha.

Ngoko ke, kutheni ufanele ukhethe i-lamination engenaso isinyibilikisi yokuprinta iibhegi zakho? Makhe sijonge kwiingenelo eziziswa zizo.

Okokuqala, ii-laminator ezingenazinyibilikisi zibonelela ngokhuseleko olungenakuthelekiswa nanto. Iindlela zemveli zokufaka i-laminator ezisekelwe kwizinyibilikisi zihlala ziquka ukusetyenziswa kwezinto eziyingozi ezifana ne-toluene kunye ne-ethyl acetate, ezibeka umngcipheko omkhulu kwimpilo kubasebenzisi kwaye zinokungcolisa ukutya okupakishiweyo. Ngokwahlukileyo koko, ukufaka i-laminator engenazinyibilikisi kususa ezi khemikhali zinobuthi, kuqinisekisa ukhuseleko kunye nokuthembeka kwenkqubo yokupakisha ukususela ekuqaleni ukuya ekupheleni.

Okwesibini, i-laminator engenazo izinyibilikisi inika umgangatho ogqwesileyo. Ukungabikho kwezinyibilikisi kuvumela inkqubo ye-lamination echanekileyo nelawulwayo, nto leyo ekhokelela kwimifanekiso ebukhali necacileyo kwiifilimu zokupakisha. Nokuba luphawu oluqinileyo kwibhegi yekofu okanye uyilo oluhle kwibhegi yokutya okulula, ii-laminator zethu ezingenazo izinyibilikisi ziqinisekisa ukuba ukubonakala kophawu lwakho kuyabonakala kukhuphiswano.

Ukongeza, ii-laminator ezingenazinyibilikisi zikhuthaza uzinzo kwaye zinobuhlobo ngakumbi nokusingqongileyo. Ngokususa izinyibilikisi, ezi matshini zinciphisa kakhulu ukukhutshwa kwee-volatious organic compounds (ii-VOC), ezaziwayo ezinegalelo kungcoliseko lomoya kunye notshintsho lwemozulu. Njengoko imfuno yokupakishwa okunobuhlobo nokusingqongileyo iqhubeka isanda, ukukhetha i-laminator engenazinyibilikisi kubonisa ukuzinikela kwakho kuzinzo kwaye kunokuphucula udumo lophawu lwakho.

Ukongeza kwezi nzuzo, ii-laminator ezingenasombululo zikwanyusa ukusebenza kakuhle kunye nemveliso. Inkqubo yokomisa engenasombululo ikhawulezisa imveliso, nto leyo ebangela amaxesha amafutshane okusebenza kunye nesivuno esiphezulu. Oku kuluncedo ngakumbi kumashishini afana nokupakisha ikofu, apho ukuhanjiswa ngokukhawuleza kunye nokutsha kubaluleke kakhulu. Nge-laminator yethu ephucukileyo engenasombululo, ungenza imisebenzi ibe lula kwaye uhlangabezane neemfuno zabathengi ngokulula.

Njengenkampani egxile kubathengi, eyona nto iphambili kuthi kukubonelela ngezisombululo ezenzelwe wena ukuhlangabezana neemfuno zakho ezithile. Iqela lethu leengcali liza kusebenzisana nawe ngokusondeleyo ukuze liqonde iimfuno zakho zokupakisha, nokuba kukutya okanye ikofu, kwaye licebise umatshini wokugquma ongenaso isinyibilikisi ofanelekileyo ukuze ufezekise iziphumo ozifunayo. Siyaqonda imingeni eyahlukileyo ejongene nomzi-mveliso wokupakisha oguquguqukayo, kwaye ukuzibophelela kwethu ekuveliseni izinto ezintsha kunye nokwaneliseka kwabathengi kusenza sahluke kukhuphiswano.

I-laminator engenazinyibilikisi itshintshe indlela epakishwe ngayo ngokhuseleko lwayo, umgangatho ophezulu, uzinzo lokusingqongileyo kunye nokusebenza kakuhle okwandisiweyo. Sithembe ukuba siza kukunika ubuchwepheshe bamva nje bokupakishwa kwe-lamination engenazinyibilikisi kunye nenkonzo yabathengi ebalaseleyo njengoko siqhubeka nokukhokela indlela kweli shishini lihlala litshintsha. Nxibelelana nathi namhlanje kwaye sikuvumele sikuncede uthabathe ukupakisha kwakho uye kwinqanaba elilandelayo.

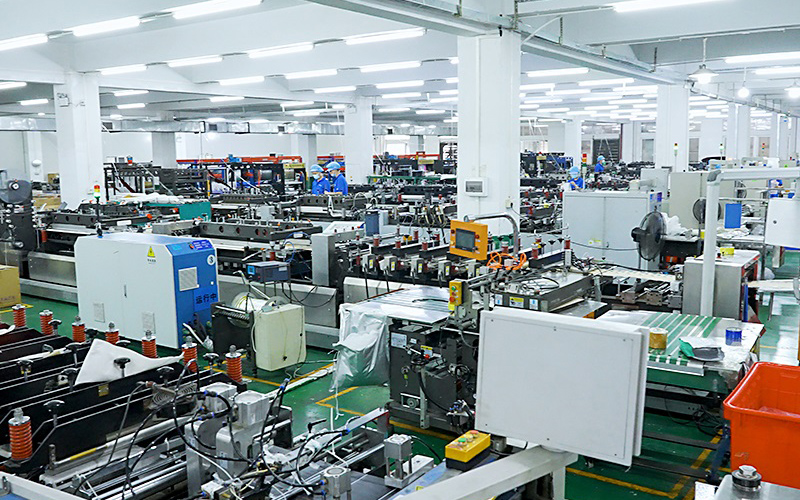

Ngenxa yokwanda kwemfuno yeengxowa zokupakisha eziguquguqukayo kwishishini lokutya neziselo, imfuneko yeengxowa zoomatshini ezisebenzayo zokwenza iye yaba yinto ebalulekileyo. Iingxowa zokwenza ziyinxalenye ebalulekileyo yenkqubo yokuvelisa, zivelisa iingxowa ezikumgangatho ophezulu ezihlangabezana nemigangatho engqongqo yeshishini. Siza kuhlola ukubaluleka kweengxowa zokwenza zibhetele kwishishini leengxowa zokupakisha eziguquguqukayo, sigxile kakhulu kwiingxowa zokutya nezekofu.

Iingxowa zokupakisha eziguquguqukayo zisetyenziswa kakhulu kushishino lokutya ngenxa yokuba ziyakwazi ukukhusela umxholo, zandise ixesha lokugcinwa kwazo kwaye zibonelela ngeendlela ezilula zokugcina kunye nokuthumela. Njengoko imfuno yabathengi yokutya okulungele ukutyiwa, izimuncumuncu kunye nekofu iqhubeka isanda, isidingo sezisombululo zokupakisha ezisebenzayo siba yinto ebalulekileyo. Kulapho oomatshini bokwenza iingxowa baqala khona ukusebenza.

Oomatshini bokwenza iingxowa benzelwe ukucubungula izinto ezisicaba ezifana neplastiki okanye i-aluminium zibe ziingxowa ezineemilo nobukhulu obahlukeneyo. Ukusebenza kakuhle kwezi matshini kuchaphazela ngokuthe ngqo imveliso, umgangatho wemveliso kunye nokusebenza kakuhle kweendleko zenkqubo yokupakisha. Ke ngoko, kumashishini akwishishini leengxowa zokupakisha eziguquguqukayo, kubalulekile ukutyala imali kumatshini wokwenza iingxowa osebenzayo.

Ngenxa yokuqhubela phambili kwezobuchwepheshe, oomatshini bokwenza iingxowa banamhlanje banikezela ngeempawu ezahlukeneyo zokuphucula inkqubo yemveliso. Oomatshini baxhotyiswe ngolawulo lobushushu oluchanekileyo, iiparameter zokutywina ezihlengahlengiswayo kunye nokukwazi ukutshintsha ngokukhawuleza, okuvumela abavelisi ukuba batshintshe ngokulula phakathi kobukhulu beengxowa ezahlukeneyo kunye noyilo. Ukongeza, bahlala bexhotyiswe ngeenkqubo ezizenzekelayo ezinokubona nokulungisa naziphi na iimpazamo kwinkqubo yokuvelisa, ngaloo ndlela kunciphisa kakhulu amathuba eemveliso ezineziphene.

Kwiingxowa zokupakisha ukutya, ukugcina imveliso icocekile kubalulekile. Umatshini wokwenza iingxowa osebenzayo uqinisekisa ukuba akukho moya uvalwayo othintela naziphi na izinto zangaphandle ezifana nokufuma kunye neoksijini ekuchaphazeleni umgangatho kunye nobomi bokusela ukutya. Nokuba kugcina ivumba kunye nencasa yekofu okanye ukwandisa ubomi bokusela ukutya okonakalayo, oomatshini bokwenza iingxowa badlala indima ebalulekileyo ekuqinisekiseni ukuthembeka kunye nokhuseleko lweempahla ezipakishiweyo.

Oomatshini bethu bokwenza iibhegi abasebenzayo abagcini nje ngokunyusa imveliso, kodwa bakwavumela iinkampani ukuba zihlangabezane neemfuno zabathengi ezitshintsha rhoqo. Ukukwazi ukuvelisa ngokukhawuleza iingxowa ezisemgangathweni ophezulu kwenza amashishini akwazi ukuqalisa iimveliso ezintsha, anikezele ngezisombululo zokupakisha ezenziwe ngokwezifiso, kwaye asebenzise amaqhinga okuthengisa anobuchule ukuze ahluke kwimarike.

Umatshini wethu wokwenza iingxowa osebenzayo utshintsha umdlalo kwishishini leengxowa zokupakisha eziguquguqukayo. Ukupakisha ukutya nekofu kufuna ukuchaneka, ukuthembeka kunye nesantya ukuhlangabezana neemfuno zabathengi kunye nokugcina imveliso icocekile. Ngoomatshini bethu bokwenza iingxowa abaphambili, iinkampani zinokuphucula iinkqubo zemveliso, ziphucule umgangatho wemveliso, kwaye zifumane ithuba lokukhuphisana kwimarike. Njengoko ishishini liqhubeka nokutshintsha, ukwamkela uphuhliso lwetekhnoloji kwimishini yokwenza iingxowa kubalulekile ekuhlaleni phambili kwimeko eguqukayo yeshishini lokupakisha ukutya.