Candy Bags: Solutions for Infused Edibles

YPAK candy bags are engineered with precision, guided by material science, compliance regulations, and the unique challenges of infused edibles. From sticky gummies to delicate chocolates, we design and manufacture bags that preserve freshness, ensure safety, and align with evolving cannabis laws and consumer expectations.

With a variety of formats, Mylar, foil, kraft-paper hybrids, PE, and compostables, we apply deep R&D to ensure that every candy bag performs reliably across flavor retention, dosage protection, and shelf readiness.

Using Candy Bags to Enhance Performance

Infused candies pose a unique set of packaging challenges:

●Oils and stickiness that can break seals or compromise film integrity

●Volatile terpenes and flavors that must be retained securely

●Precise dosing and safety, often subject to strict labeling and access rules

●Demand for premium branding, combining form and regulatory function

Our candy bags are built to solve these issues at every level, from materials to closure systems.

Applying High-quality Materials for Candy Bags

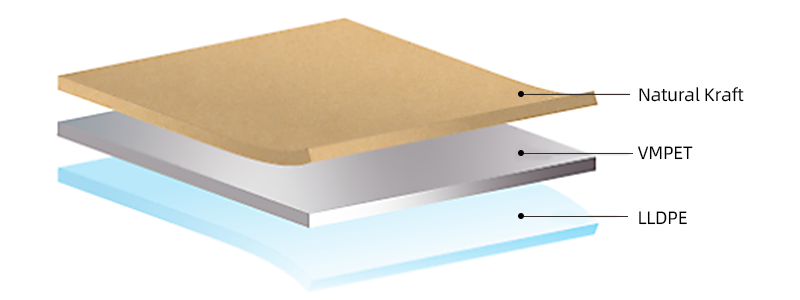

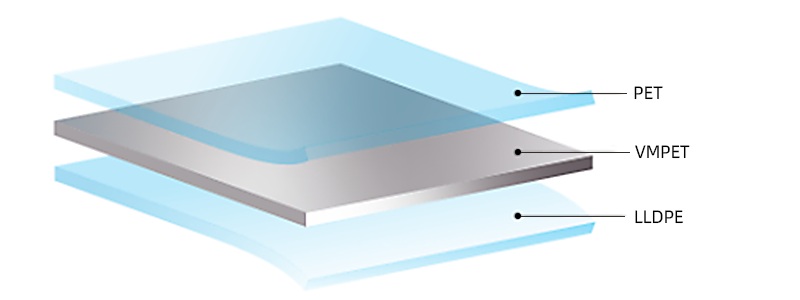

YPAK candy bags are manufactured using custom-layered films, tuned for product compatibility and performance. Formats include:

●Mylar multi-layer films: Excellent barrier, UV resistance, smooth for printing

●Foil laminates: Ideal for fat-rich candies like chocolates

●PE-based films: Resealable and recyclable options for sustainability-focused SKUs

●Kraft-paper hybrids: Textured finish with inner liners for aroma and moisture protection

●Compostable films (PLA/PBAT): Great for small single-use candy units

●Cellulose and lacquered paper: Breathable, biodegradable options for dry mints or teas

Each material stack is customized with food-safe, non-reactive adhesives, oil-resistant coatings, and high seal integrity, ensuring performance even under heat or handling stress.

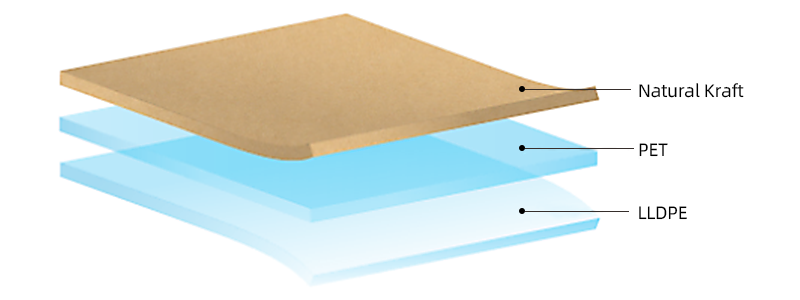

Advanced Film Construction for Candy Bags

Our film structures are engineered for the candy category’s specific challenges. Multi-layer laminates offer moisture resistance, aroma barrier, and puncture protection, with customizable layers for recyclability, compostability, or extended shelf life. We match the right film to your candy’s form, whether it’s chewy, powdery, or coated, for both protection and presentation.

We develop multi-layer barrier structures based on:

●OTR/MVTR targets (oxygen and moisture transmission rates)

●Product interaction (candy oils, fats, terpenes)

●Child-resistance and tamper performance

●Mechanical durability (puncture, tear, flex resistance)

Our standard candy bag construction might include:

●Outer layer (PET, kraft): Brand surface + print compatibility

●Core barrier (EVOH, foil): Aroma and oxidation protection

●Sealant layer (PE, PLA, PBAT): Safe contact and closure control

Candy Bags R&D and Performance Test

Innovation drives our packaging solutions. Our R&D team tests new materials, formats, and features tailored to the unique demands of candy products, from stickiness and sugar migration to temperature resilience. Performance tests include material selection, shelf-life simulation, and Regulatory and compliance testing to ensure your bags stay fresh, functional, and customer-ready.

All candy bag formats from YPAK go through:

1. Material Selection and Testing

●Compatibility with sugar oils, chocolate fats

●Resistance to melting or packaging degradation

●Odor containment validation using GC/MS

2. Shelf-Life and Storage Simulation

●Simulated exposure to heat, light, and humidity

●Flex and puncture stress testing under filled weight conditions

3. Regulatory and Compliance Testing

●CR zippers tested to 16 CFR 1700.20

●Tamper-evident perforations and heat seals

●Legal label layout zones for THC content, batch, and allergens

YPAK Candy Bags Manufacturing Process

Every candy bag from YPAK is crafted with precision through a three-step process designed for consistency, durability, and shelf appeal.

Film Production

●Precision lamination and extrusion across materials

●Custom barrier optimization based on candy type

Bag Conversion

●Stand-up, flat, gusseted, and pillow candy bag formats

●Zipper, press-seal, and heat-sealed closure options

●CR-compliant zippers and tear indicators embedded during formation

Quality Control

●Seal burst, peel force, and leak path testing

●Vision-based inspection for alignment and print accuracy

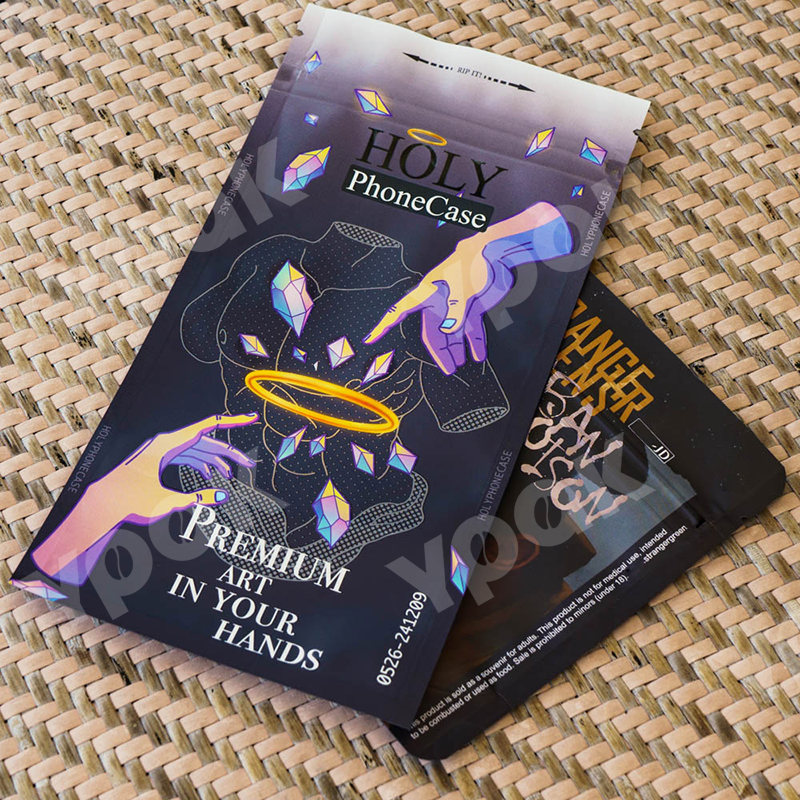

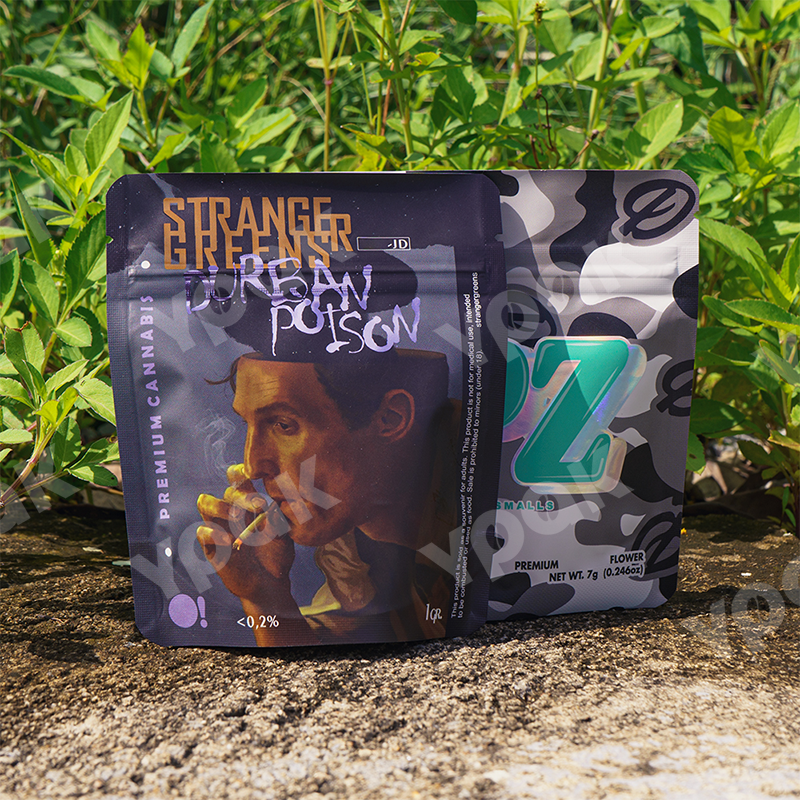

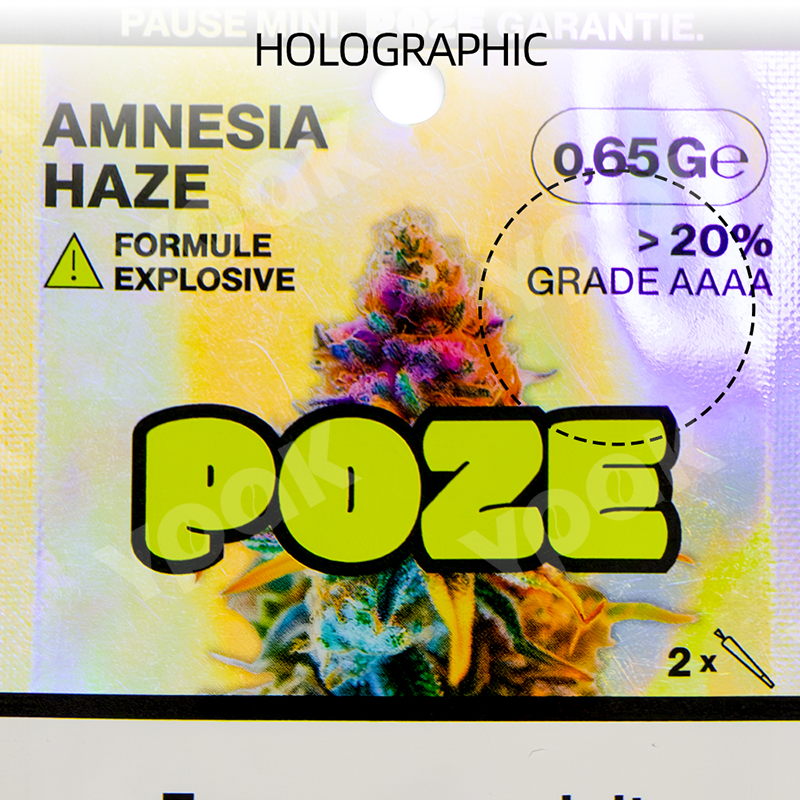

Printing Technologies for Candy Bags

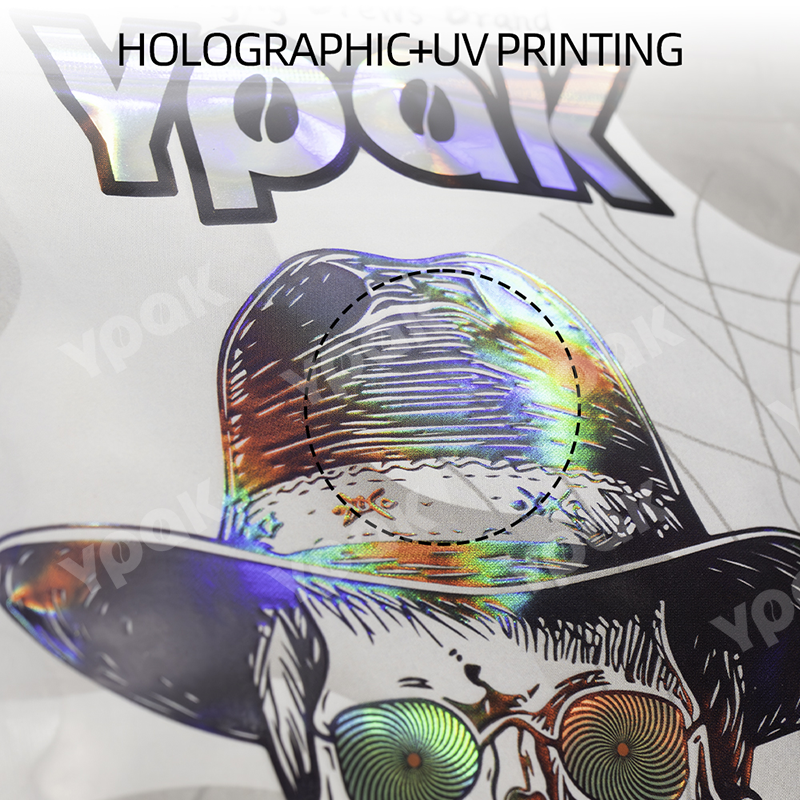

YPAK leverages advanced printing techniques to bring your candy brand to life. We offer high-definition rotogravure and digital printing options for vibrant, photo-quality graphics on a variety of substrates. From metallic effects to matte finishes and spot varnishes, every detail is optimized for visual impact and brand recognition on retail shelves.

Digital Printing

●Flexible for small batch candy runs, seasonal releases

●Batch numbers, QR codes, and variable strain labeling

●Photorealistic branding up to 1200 dpi

Flexographic Printing

●Ideal for mass production with consistent PMS color fidelity

●Specialty inks: soft-touch, matte/gloss contrast, metallics

●All inks are low-migration and FDA/Health Canada compliant for edibles

Child Resistance, Tamper Features, and Labeling Zones on Candy Bags

●Certified child-resistant closures are available across all major formats

●Tamper-evident options: Perforated seals, heat tabs, UV-reactive indicators

●Smart label zones designed for compliance: THC, nutrition, warnings, traceability

We offer RFID/QR integration for serialized verification or supply chain tracking, embedded at the print or bag conversion stage.

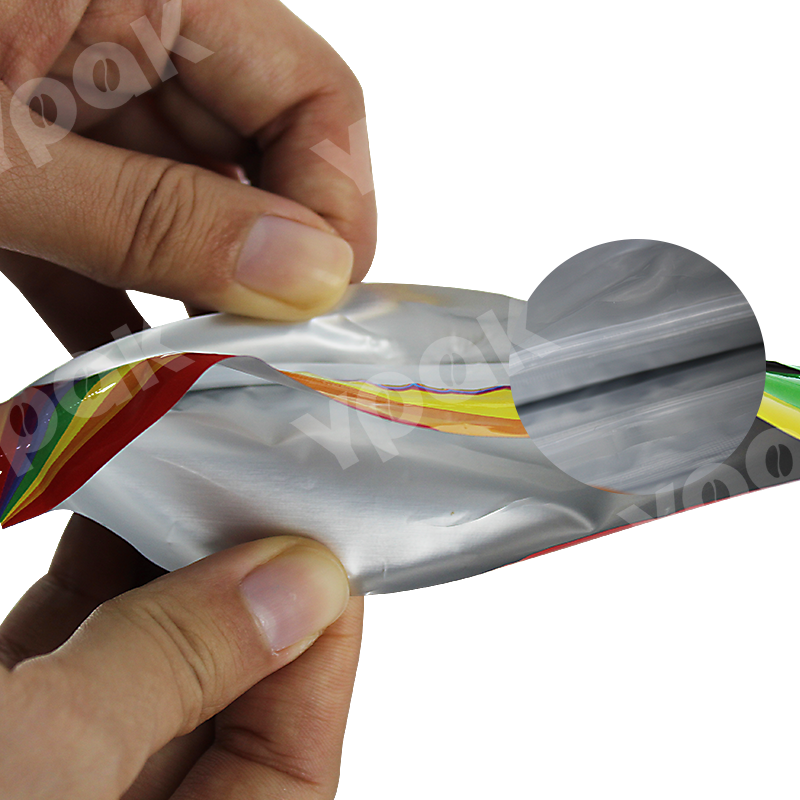

Candy Bags Resealable Closures

Resealability in candy bags is critical to ensure freshness, safety, and child resistance. At YPAK, we engineer sealant layers that:

●Tolerating oils and moisture from infused candies without compromising bond strength

●Support multiple sealing technologies, impulse, rotary, or ultrasonic, across different production lines

●Maintain seal integrity even in child-resistant configurations or during repeated opening and closing cycles

We also validate seals using peel force, burst pressure, and leak path testing, ensuring each bag performs reliably in distribution, retail, and consumer use.

Sustainable Solutions for Candy Bags

We offer a wide range of sustainability-forward bag options, including:

●Mono-material PE designs: Fully recyclable and lightweight

●PCR-content films: Up to 50% post-consumer Mylar or PE

●Industrial/home compostable candy bags using PLA or PBAT layers

●Minimalist barrier films with reduced thickness and equivalent performance

Candy Bags Smart Features Under Development

YPAK is actively developing enhanced candy bag options, such as:

●Humidity/VOC-sensitive ink indicators for freshness tracking

●Printed smart labels that change color with oxygen exposure

●Embedded NFC chips for dosage guidance or regulatory links

●Blockchain-linked packaging identity systems for verified strain history

Elevate Your Edibles Using YPAK’s Cannabis Candy Bags

YPAK understands that cannabis-infused candy requires packaging that is able to preserve taste, ensure safety, and elevate experience. Our cannabis candy bags are designed to do just that: lock in freshness, delight users, and meet the strictest compliance standards.

Using Specialized Candy Bags Matter

Cany Bags' functions are to:

●Preserve Flavor Integrity: Sweet formulations demand neutral packaging that won’t affect taste.

●Preserve Potency: Terpenes and cannabinoids degrade with exposure to oxygen, light, and moisture.

●Enhance Safe Consumption: Child-resistant designs are essential to prevent accidental ingestion.

●Elevate Premium Presentation: In a growing market, packaging must stand out visually and tactilely.

YPAK’s candy bags are engineered to meet all these needs, protecting your product while positioning it as premium retail and digital assets.

Our Candy Bags lines Are Crafted to Amplify Your Product

Here’s how each of our lines is crafted to amplify your product:

1. Stand-Up or Pillow Candy Bags

Stand-up candy bags are Ideal for micro-dose candies, single gummies, or larger soft chews:

●Food-Grade Inner Liners: Preserve sweetness and texture without off-flavors.

●Barrier Performance: Multi-layer PET/EVOH laminates block moisture and oxygen.

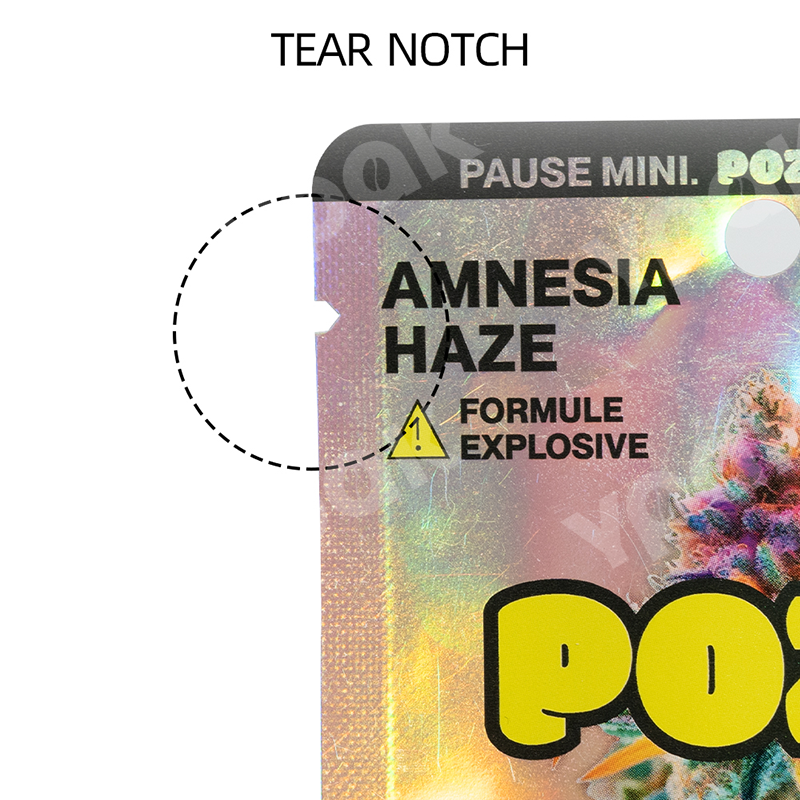

●Resealable Zipper & Tear Notch: Supports compliance while being easy for adults.

●Flexible Shapes: Choose between pillow or gusseted formats to match brand identity.

●Print & Finishes: Available with soft-touch, gloss, matte, or metallic options to stand out on the shelf.

2. Gusseted Candy Bags for Multi-Piece Packs

Perfect for family-size packs, party favors, or sampler gift sets:

●Wide-Bottom Design: Grows when filled and stands upright with ease.

●Controlled Portioning: Ideal for dosing information and ingredient labeling.

●Enhanced Barrier Layers: Maintains quality across multiple doses.

●Label-Friendly Surfaces: Smooth panels for QR codes, nutrition panels, and strain identifiers.

3. Child‑Resistant (CR) Candy Bags

Child-resistant candy bags are essential for gummies and edibles, especially in households with children:

●Certified CR Zippers: Push-slide or press-seal mechanisms engineered for adult usability and child-resistance (CFR 1700.20).

●Repeated-Use Integrity: Our zippers maintain safety performance over countless opens.

●User Guidance Icons: Embossed markings or printed instructions guide proper opening, especially for older users.

●Compliant & Confidence-Building: Helps brands meet regulations and earn consumer trust.

4. Holographic Kraft & Hybrid Candy Bags

For brands leaning into craft or wellness imagery:

●Eco Aesthetic: Kraft outer panels present artisanal appeal.

●Barrier Power: Holographic or metallized interiors offer high-level protection.

●Eye-Catching Contrast: Natural textures meet futuristic shine—ideal for gifting and specialty markets.

●Sustainable Twist: Add a kraft finish without sacrificing packaging performance.

5. Resealable Soft-Touch Gift Candy Bags

Soft-Touch candy bags are designed for luxury edibles and shareable formats:

●Premium Finishes: Velvet-like touch paired with soft gloss or metallic accents.

●Elegant Reuse: Quality zippers support repeated sealing and multi-use.

●Gift-Worthy Details: Combine lanyard handles, ribbon ties, or die-cut windows shaped for brand flair.

●Unboxing Appeal: Perfect for pop-ups, luxury subscriptions, and gifting.

Benefits of our Candy Bags for Your Business

| Feature | Brand & Consumer Impact |

| Multi-Layer Mylar Barrier Film | 6-12 month freshness and aroma protection |

| Certified CR Zippers | Meets regulations and builds trust with caregivers |

| Food-Safe Interiors | Prevents flavor distortion for pure taste every time |

| Flexible from factors | Supports a range of SKUs from single gumballs to sampler packs |

| Premium Print & Finish Options | Drives Impulse buys with visual and tactile appeal |

| Customizable Label Zones | Readiness for Compliance and traceability needs |

| Fully customizable structures | Tailored to brand identity |

Reach Your Eco-conscious Customers With Our Sustainable Candy Bags

Consumers care about sustainability, and YPAK delivers:

●Mono‑Material Designs: Fully recyclable via LDPE streams.

●PCR Film Options: Up to 50% recycled content without losing freshness.

●Lightweighting Innovations: Up to 30% thinner films with full barrier protection.

●Compostable Alternatives: PLA/PBAT blends for eco-friendly single-use packaging.

Now you can deliver indulgence and environmental adjacencies with every bag.

Why You Should Use Our High-Quality Candy Bags

Our candy bags are rigorously tested to ensure they perform in real-world conditions:

●Accelerated Aging & UV Testing: Keeps potency and flavor even after shipping and retail display.

●Food Safety Certification: Inner liners pass migration and sensory neutrality standards.

●CR Testing Over Lifespan: Confirmed child-resistance after extensive use.

●Packaging Compliance Audit: Labels, materials, and tamper evidence are designed with regulations in mind.

Our data-driven masking means confidence in every candy release.

Leverage Our Scalable Candy Bags Solutions for Your Business

At YPAK, we meet brands where they are, whether you're launching a small-batch product or supplying national retailers. Our flexible production model adapts to your needs with low MOQs for emerging businesses and high-volume runs for established names. From custom printing to material selection, every solution is built to scale with you, without compromising quality, speed, or brand impact.

From boutique startups to national brands, here is how we help you:

●Prototype & Learn Fast: 5k–50k test runs with performance validation and design mockups.

●Flex Production Runs: Suitable for seasonal SKUs and limited-time flavors.

●In-House Print Mastery: Digital and flexo services with foil, embossing, and tactile coatings.

●Barrier Performance Assurance: Our trials guarantee no taste compromise or aroma loss.

Growing your candy lineup has never been easier, or more precise.

Advantages of Partnering With YPAK for Your Candy Bags

Partnering with YPAK means more than just getting packaging, it means gaining a reliable, forward-thinking collaborator dedicated to your brand’s growth.

We understand that in competitive markets like cannabis, packaging is not just a vessel, it’s your first impression, your silent salesperson, and a key factor in consumer trust.

That’s why we approach every project with precision, flexibility, and a deep understanding of your product’s unique demands.

From the outset, we provide hands-on support throughout the process, from material selection and structural engineering to print execution and post-production.

Our capabilities span custom-printed pouches, sustainable films, and complex finishes, all supported by a global network of production partners to ensure consistent quality and lead times.

But what truly sets YPAK apart is our responsiveness. We adapt to your timeline, scale, and SKU complexity, whether you're launching a limited seasonal run or managing multi-market distribution.

With low MOQs, smart inventory options, and scalable logistics, we make it easier for you to stay agile in fast-moving retail environments.

Add to that our commitment to sustainability, ongoing R&D, and a proactive quality control system, and you get a packaging partner who’s as invested in your long-term success as you are. With YPAK, you don’t just get packaging, you get performance, partnership, and peace of mind.

Let’s Talk Possibilities for Your Candy Bags

Want to explore new pack formats?

●Single-serve CR bag with clear window to showcase color-coded gourmet gummies.

●Family-size gusset bag with variable data printing for limited runs.

●Holiday gift pouch with ribbon handle and holographic interior for viral display.

We’re ready to bring your vision to life with our R&D support, performance testing, and pilot flexibility, scale-to-scale.

Contact our R&D + Sales Team today to start building candy packaging that fits your brand.