What exactly are PCR materials?

1. What are PCR materials?

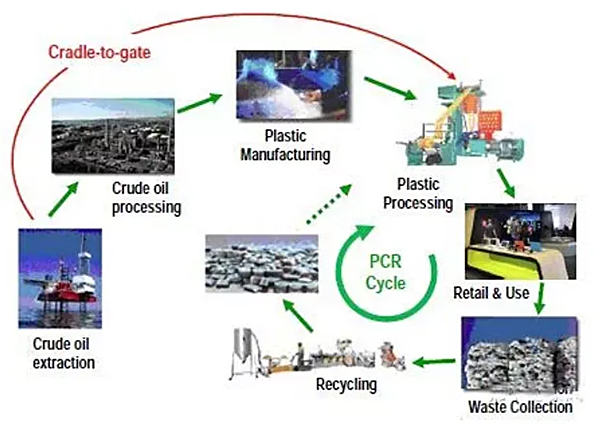

PCR material is actually a kind of "recycled plastic", the full name is Post-Consumer Recycled material, that is, post-consumer recycled material.

PCR materials are "extremely valuable". Usually, waste plastics generated after circulation, consumption and use can be turned into extremely valuable industrial production raw materials through physical recycling or chemical recycling, realizing resource regeneration and recycling.

For example, recycled materials such as PET, PE, PP, and HDPE come from the waste plastics generated from commonly used lunch boxes, shampoo bottles, mineral water bottles, washing machine barrels, etc. After reprocessing, they can be used to make new packaging materials. .

Since PCR materials come from post-consumer materials, if they are not properly processed, they will inevitably have the most direct impact on the environment. Therefore, PCR is one of the recycled plastics currently recommended by various brands.

2. Why are PCR plastics so popular?

• (1). PCR plastic is one of the important directions to reduce plastic pollution and contribute to "carbon neutrality".

After the unremitting efforts of several generations of chemists and engineers, plastics produced from petroleum, coal, and natural gas have become indispensable materials for human life because of their light weight, durability, and beauty. However, the extensive use of plastics has also resulted in the generation of large amounts of plastic waste. Post-consumer recycling (PCR) plastic has become one of the important directions to reduce plastic environmental pollution and help the chemical industry move towards "carbon neutrality".

Recycled plastic pellets are mixed with virgin resin to create a variety of new plastic products. This method not only reduces carbon dioxide emissions, but also reduces energy consumption.

• (2). Use PCR plastic to further promote waste plastic recycling

The more companies that use PCR plastics, the greater the demand, which will further increase the recycling of waste plastics and gradually change the model and business operations of waste plastic recycling, meaning less waste plastics will be landfilled, incinerated and stored in the environment. in natural environment.

• (3). Policy promotion

The policy space for PCR plastics is opening up.

Take Europe as an example, the EU plastics strategy and the plastics and packaging tax legislation in countries such as Britain and Germany. For example, the UK Revenue and Customs has issued a "Plastic Packaging Tax". The tax rate for packaging with less than 30% recycled plastic is 200 pounds per ton. Taxation and policies have opened up the demand space for PCR plastics.

3. Which industry giants are increasing their investment in PCR plastics recently?

At present, the vast majority of PCR plastic products on the market are still based on physical recycling. More and more international chemical industries are following the development and application of chemically recycled PCR plastic products. They hope to ensure that the recycled materials have the same performance as the raw materials. , and can achieve "carbon reduction".

•(1). BASF’s Ultramid recycled material obtains UL certification

BASF announced this week that its Ultramid Ccycled recycled polymer produced at its Freeport, Texas, plant has received certification from Underwriters Laboratories (UL).

According to UL 2809, Ultramid Ccycled polymers recycled from post-consumer recycled (PCR) plastics can use a mass balance system to meet recycled content standards. The polymer grade has the same properties as the raw material and does not require adjustments to traditional processing methods. It can be used in applications such as packaging films, carpets and furniture, and is a sustainable alternative to raw materials.

BASF is researching new chemical processes to continue converting some waste plastics into new, valuable raw materials. This approach reduces greenhouse gas emissions and fossil raw material inputs while maintaining product quality and performance.

Randall Hulvey, BASF North American Business Director:

“Our new Ultramid Ccycled grade offers the same high mechanical strength, stiffness and thermal stability as traditional grades, plus it will help our customers achieve their sustainability goals.”

•(2). Mengniu: Apply Dow PCR resin

On June 11, Dow and Mengniu jointly announced that they have successfully commercialized post-consumer recycled resin heat shrinkable film.

It is understood that this is the first time in the domestic food industry that Mengniu has integrated its industrial ecological strength and united with plastic raw material suppliers, packaging manufacturers, recyclers and other industry chain parties to realize the recycling and reuse of plastic packaging, fully applying post-consumer recycled plastics as a Product packaging film.

The middle layer of the secondary packaging heat shrinkable film used by Mengniu products comes from Dow's PCR resin formula. This formula contains 40% post-consumer recycled materials and can bring the recycled material content in the overall shrink film structure to 13%-24%, enabling the production of films with performance comparable to virgin resin. At the same time, it reduces the amount of plastic waste in the environment and truly realizes the closed-loop application of packaging recycling.

•(3). Unilever: Switching to rPET for its condiment series, becoming the UK’s first 100% PCR food brand

In May, Unilever's condiment brand Hellmann's switched to 100% post-consumer recycled PET (rPET) and launched it in the UK. Unilever said that if all this series were replaced with rPET, it would save about 1,480 tons of raw materials every year.

Currently, nearly half (40%) of Hellmann's products already use recycled plastic and hit shelves in May. The company plans to switch to recyclable plastic for this series of products by the end of 2022.

Andre Burger, vice president of food at Unilever UK and Ireland, commented: “Our Hellmann’s condiment bottles are our first food brand in the UK to use 100% post-consumer recycled plastic, although in this shift There have been challenges, but the experience will enable us to accelerate the use of more recycled plastic across Unilever’s other food brands.”

PCR has become a label for ECO-friendly materials. Many European countries have applied PCR to food packaging to ensure 100% ECO-friendly.

We are a manufacturer specializing in producing the coffee packaging bags for over 20 years. We have become one of the largest coffee bag manufacturers in China.

We use the best quality WIPF valves from Swiss to keep your coffee fresh.

We have developed the eco-friendly bags, such as the compostable bags and recyclable bags,and the latest introduced PCR materials.

They are the best options of replacing the conventional plastic bags.

Attached our catalogue, please send us the bag type, material, size and quantity you need. So we can quote you.

Post time: Mar-22-2024