Custom Recyclable Flat-Bottom Bags——Why do people choose it?

Recyclable Flat-Bottom Bags

Flat-bottom pouches are a highly favored packaging format known for their excellent stability and ability to stand upright on shelves. YPAK uses high-quality mono-material PE (polyethylene) to produce recyclable flat-bottom pouches. This solution is ideal for brands that want to appeal to eco-conscious consumers. We construct recyclable pouches entirely from 100% mono PE, typically using three to four-layer films that provide both durability and essential barrier protection, often enhanced with an EVOH coating for superior oxygen resistance.

As one of the leading manufacturers of recyclable flat-bottom bags in China, we efficiently handle high-volume orders at competitive prices, supported by our strategic location near major raw material suppliers. Our recyclable mono-PE films can be sourced daily, and our in-house, fully automated production lines ensure consistency and scale.

Branding Recyclable Flat-bottom Bags

YPAK provides fully customized recyclable flat-bottom pouches tailored to your product's size, material demands, and branding vision. Our team of high-skilled engineers is dedicated to creating packaging with consistent quality. We combine sophisticated design skills with in-depth knowledge of sustainable materials. Our recyclable flat-bottom pouches are very well-known and trusted by established brands, wholesale companies, and eco-conscious retailers because of their eco-friendly build and premium finish.

Ordering Recyclable Flat-Bottom Bags Directly From the Factory

YPAK owns proprietary pouch-making technology, giving us full control over quality and innovation. With years of specialized R&D, our bags stand at the intersection of sustainability, performance, and scalability. We offer a catalog of diverse bag types, designed to meet the varying packaging needs of eco-conscious brands worldwide.

Custom-Made Recyclable Flat-Bottom Bags for Your Target Customers

To improve shelf appeal, we provide full customization options including branded graphics, product labeling, and finishes. Offered in a variety of sizes, recyclable flat-bottom pouches are flexible enough to satisfy product packaging needs, therefore providing a more sustainable replacement for traditional packaging types.

Advanced Recyclable Materials for Your Flat Bottom Bags

Mono-Material LDPE Systems- Recyclable Flat-Bottom Bags

We build our recyclable flat-bottom bags using 100% LDPE(Low-Density Polyethylene), a type of PE (Polyethylene) that’s soft, flexible, and compatible with #4 soft plastic recycling streams, enabling a closed-loop system. We design co-extruded PE layers with excellent barrier and heat-seal characteristics.

Co-extruding layers of LDPE-based film structures provides:

Effective oxygen and moisture barrier properties (comparable to traditional multi-material laminates)

Reliable heat-seal performance

This design keeps end-of-life recyclability intact while maintaining the protective functionality needed for high-quality food and coffee packaging.

Designed for your brand's packaging needs, every choice is modifiable in terms of barrier strength, printability, and thickness.

Recyclable Flat-Bottom Bags Structural & Design Engineering

Our product engineers configure every element of the recyclable flat-bottom bag:

Customized Footprints: From compact, single-serving snack formats to large-format bags for bulk items like coffee or pet food, our bags’ dimensions are precisely calculated to the product's volume and density, eliminating unnecessary material usage.

Material Science for Recyclability: Our engineering solution lies in creating multi-layer films that provide the necessary barrier properties (against oxygen, moisture, and light) while being compatible with existing recycling systems.

Mono-Material Laminates: The industry is rapidly moving away from traditional multi-material laminates (e.g., PET/Alu/PE), which are difficult to recycle. To meet the market’s demand, YPAK crafts mono-material laminates, typically based on polyethylene (PE) or polypropylene (PP). These structures consist of multiple layers of the same polymer family, sometimes with different densities or orientations, to achieve your desired performance characteristics.

Advanced Barrier Coatings: To replace non-recyclable layers like aluminum foil and metallized films, our engineers utilize ultra-thin, high-performance barrier coatings. These are often silicon oxide (SiOx) or aluminum oxide (AlOx) based, applied in a transparent layer that is so minimal it doesn't contaminate your bag’s recycling stream.

Recyclable Adhesives: The adhesives used to laminate the film layers are also being re-engineered. We consistently design new formulations to be compatible with the primary polymer, ensuring that your entire package can be processed as a single material.

Integrating Functionality with Recyclability in Mind for Flat-Bottom Bags

The true test of a well-engineered recyclable bag is its ability to incorporate convenient features without compromising its end-of-life recyclability function.

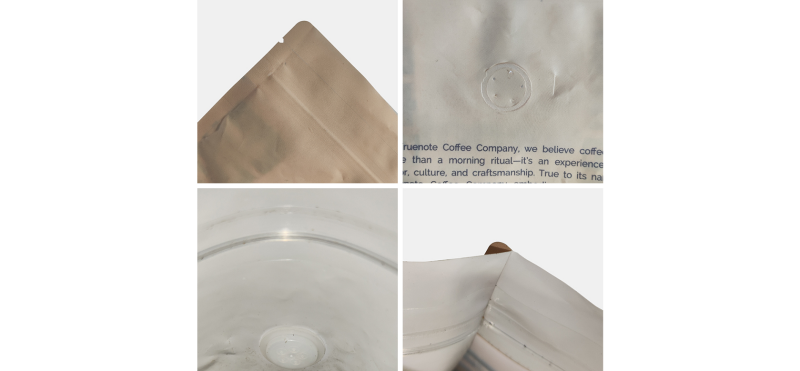

WIPF Degassing Valves: These are essential for products like freshly roasted coffee that release carbon dioxide. We offer an option to add WIPF degassing valves on your flat-bottom pouches that are available in recyclable and compostable versions. These one-way valves are typically made from the same polymer as the bag (e.g., PE or PP), allowing for seamless integration and recycling. The engineering focus is on the precise location of the valve for optimal degassing and the compression type, which can be tailored to the specific product and filling process.

Resealability:

• Slider-Free and Pocket Zippers: To avoid the use of mixed materials often found in conventional sliders, we have shifted our focus to press-to-close zippers. "Slider-free" zippers are integrated into the bag's film and are made from the same recyclable polymer.

• "Pocket zippers" offer a unique solution where the zipper is shielded by a flap of the flat-bottom bag's material, preventing product from clogging the tracks and ensuring a reliable seal. The engineering of these zippers involves intricate die-cutting and heat-sealing processes to create a user-friendly and robust closure.

• Recyclable Tin-Ties: Tin-ties are a popular choice for a classic premium feel. Our sustainable options now feature paper-based ties or those designed to be easily removable by the consumer before recycling. We carefully select the adhesive used to attach the tie so as not to interfere with the recycling process of the flat-bottom pouch.

Micro-Perforations and Easy-Tear Features: Laser-scored micro-perforations offer a clean and convenient way for consumers to open the package. Our technology allows for precise control over the tear initiation and propagation, eliminating the need for tear notches that can sometimes create small, loose plastic pieces. The perforations are engineered to maintain the package's barrier integrity until it is intentionally opened.

Efficiency and Visual Distinction:

• Rounded Corners: Beyond aesthetics, rounded corners provide a more comfortable and ergonomic feel in the hand. This seemingly simple feature requires precise die-cutting and sealing to ensure the corners are strong and do not become weak points in the package.

• Die-Cut Windows: Offering a glimpse of the product inside is a powerful marketing tool. In recyclable bags, these windows are not a separate plastic film but rather a transparent section of the bag's mono-material structure. Our engineers maintain the barrier properties of the window area, often through the application of the aforementioned clear barrier coatings.

These options offer your brand full control to design recyclable flat-bottom bags aligned with product protection and user experience goals.

Print & Finish Customization for Your Recyclable Flat-Bottom Bags

Visual branding is as important as function. Our recyclable flat-bottom bags can help your brand stand out through:

Digital Printing: This is perfect for small batches, seasonal offerings, and product test launches.

Rotogravure Printing: Deliver Vibrant designs, high-resolution graphics. Compatible with mono-material films when using recyclable-grade inks.

Surface finishes: Choose subtle, recyclable-friendly options like embossing to add texture without added materials.

You decide how your recyclable flat-bottom bag looks, feels, and connects, while retaining recyclability.

Precision Production Workflow Recyclable Flat-Bottom Bags

Every YPAK recyclable flat-bottom bag passes through a tightly controlled, end-to-end production pipeline designed for quality, consistency, and sustainability:

Structural Engineering & Die line Development: Custom CAD-based die lines ensure exact bag geometry and optimal material usage.

High-Barrier Film Lamination: Mono-material PE structures are laminated to meet your specific oxygen and moisture barrier requirements, all while remaining fully recyclable.

Accessory Integration: Add functional features like WIPF valves, resealable zippers, tear notches, die-cut windows, and embossing, all customized to your product needs.

Finishing & Conversion: Includes precision sealing, side gusset formation, bottom panel definition, trimming, and 100% QC inspection.

Flexible Order Quantities: Start small with a 1,000-unit MOQ for prototyping or scale up to high-volume rotogravure printing runs, with the same commitment to quality.

Sustainability & Compliance for Recyclable Flat-Bottom Bags

As a trusted leader in sustainable packaging, YPAK helps your brand meet both environmental and regulatory goals:

Labeling Compliance: Bags can be marked with EU, UK, or US recycling symbols, clearly placed on the base for consumer guidance.

Compostable Certifications: For non-recyclable options, we offer EN13432 / ASTM D6400 certified compostable bags.

Recycled & Renewable Materials: We choose between pure PE, sugarcane-based bio-PE, or post-consumer recycled content, aligned with your brand’s footprint and story.

Every recyclable flat-bottom bag we produce reflects our commitment to functional sustainability.

Technical Support & Industry Experience in Recyclable Flat-Bottom Bags

YPAK isn’t just a manufacturer. We act as your packaging technology partner as well:

Custom Design & Support: From die line creation to 3D mock-ups and structural feedback, we support you throughout design planning.

Production Transparency: Get real-time updates with photos or videos during each manufacturing phase.

Dedicated Account Management: From initial sampling to worldwide delivery of your recyclable flat-bottom bags, we handle the logistics so you can focus on your brand.

Our mission is to deliver recyclable flat-bottom bags with technical precision, global reach, and full-service customer care.

Customization and Green Initiatives with Recyclable Flat-Bottom Bags

Customize Your Recyclable Flat-Bottom Bags with Sustainability in Mind

We make sustainability adaptable to your brand. Our recyclable flat-bottom bags are fully customizable:

Recyclable mono-material 100% PE

Custom oxygen, moisture, and aroma barrier layers

Film thickness tailored to product type

Recyclable-friendly finish options like embossing to match your brand identity

Elevating Shelf Impact & Branding with Recyclable Flat-Bottom Bags

Our recyclable flat-bottom bags enhance both visual appeal and customer experience:

Vivid printing (digital or rotogravure)

Special effects like spot UV, metallic foil, matte/satin finishes, embossing, and holographic

Custom windows or partial transparency, designed for product visibility without compromising recyclability

Feature-Rich Recyclable Flat-Bottom Bags for Everyday Use

User-friendly features and eco-conscious design:

Aroma-preserving degassing valves for coffee packaging

Zippers and tin ties for easy resealing

Tear notches, rounded corners, and dual-opening options for intuitive use

Every feature of our recyclable flat-bottom bags is customized for functionality and customer experience.

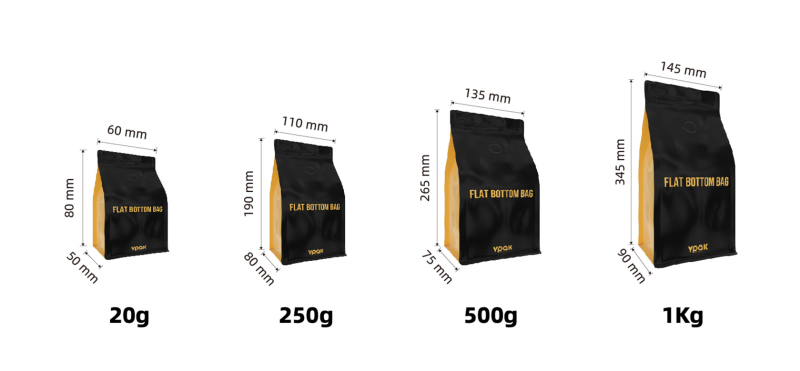

Custom Sizes & Specs for Recyclable Flat-Bottom Bags

From idea to high-volume scale:

Low MOQs (starting at 1000 units) for rapid prototyping with digital print

Large-capacity formats (up to 5,000g) with customizable gusset depths

Scalable solutions with fast lead times for growing brands

Verified Sustainability for Recyclable Flat-Bottom Bags

We help you turn packaging into a transparent sustainability story:

Proper recycling logos, disposal guidance, and regulatory-compliant labeling

Barrier and material specifications sheet for EU, UK, and US requirements

Optional third-party support: CO₂footprint tracking, and recycled material sourcing

Enhance your green positioning with claims consumers can trust.

Global Expertise in Recyclable Flat-Bottom Bags

YPAK partnership takes your brand to the next level:

Live mock-up reviews, dieline feedback, and 3D sampling

End-to-end manufacturing: converting, QC, and finishing

Global shipping coordination through North America, Europe, and Asia warehouses

Your recyclable flat-bottom bags, delivered with precision, service, and technical confidence.

Request Your Free Recyclable Flat-Bottom Bag Samples

Custom size, film type, and print mock-up

Access to spec sheets and sustainability documentation

Book a live consultation with our engineers

You're creating a branded experience with YPAK recyclable flat-bottom bags. You're investing in packaging that is:

Fully customized for your product

Impactful at the point of sale

Backed by certified sustainability

Designed for performance and ease of use

Sustainable Flat-Bottom Bags, Customized for Your Business Needs

|

Core Pillar |

Custom Features & Benefits |

| Material Engineering | LDPE mono-material systems, tailored barrier & thickness |

| Structural Design | Custom shapes, gussets, volume-optimized; optional zip, tin-tie, valves, tear-lines |

| Material Engineering | LDPE mono-material systems, tailored barrier & thickness |

| Structural Design | Custom shapes, gussets, volume-optimized; optional zip, tin-tie, valves, tear-lines |

| Visual & Finish Customization | Full-color print, special finishes, windows, embossing, spot UV |

| QA & Regulatory Compliance | Multi-stage QC, regulatory logos/certifications, material traceability |

| Service & Logistics | Mock-up support, turnkey production, real-time oversight, low MOQ, global delivery |

| Eco-Branding Support | Recyclable labeling, CO₂/LCAs, compostable certifications, consumer instruction |

Packaging Design Consultation: Let’s design your custom recyclable flat-bottom bag, with features and films that solve your brand’s needs.

Sample Production: Contact us for digitally printed mock-ups within 3-5 days to evaluate feel, color, and fit.

Scale Strategy Session: rotogravure-print options for high-volume production with robust barrier performance.