The Comprehensive Manual to Personalized Coffee Bags: From Creation to Distribution

Your coffee is different. Therefore, its packaging ought to be different too. The best form of custom coffee bags is with a proper and unique design. The bag is the first thing that people see, it will bit the coffee taint onto it from coming out from the bag itself; moreover when overstocked bags line and sit together together when.

In this tutorial, we will take you through the entire procedure. We will discuss main decisions, how to order in detail, and design advice. We will also provide you with frequently made mistakes that you should avoid. Vendor packages such as YPAK COFFEE POUCH are a valuable place to learn about the full range of packaging material selection. You can use their options as a starting point.

Knowledge of Your Choices: Central Custom Coffee Bag Selections

The bag you choose must have countless tiny variations that need to be made constantly 'Snap' and so much money is involved in style' This is the bag that you've chosen! It is a matter for both customers and manufacturers who make such bags; by understanding your choices, you can move through this stage of production smoothly while paving the way for greater opportunities in the future. Totally personalized coffee bags essentially reflect exactly what you envision.

Choosing the Right Material

Coffee bag is made up of different layers. Each one of the layers has its own function. Some of those layers keep off oxygen, water and light; on some others are printed on or give the brew strength. wholesale cotton bags

Different materials have different benefits. The answer is whichever that best fits with the brand and aims.

| Material | Key Benefit | Best For |

| Kraft Paper | Eco-friendly, and looks close to nature. | Brands that want to project an organic feel. |

| PLA (Compostable) | Environmentally friendly and made from plants. | Brands that prioritize sustainability. |

| PE (Polyethylene) | Flexible, prevents moisture well. | The inner lining of most bags that is safe. |

| MET-PET | Bright, metallic appearance, strong barrier. | Brands that want to be modern and add protection. |

| Aluminum Foil | The most effective barrier against oxygen and light. | The longest period of shelf life and the freshest taste. |

Many customers want to be environmentally friendly. Studies indicate that more than 60% of consumers would change their behavior to help reduce harm to the environment. So, materials such as PLA is starting to replace other materials to make custom coffee bags.

Choosing the Perfect Bag Style

How your bag is programmed and engineered does affect how it looks on the shelf and how the consumer uses it. Each type of personalized coffee bags has its own pros and cons.

Stand-Up Pouches (Doypack): They are very trendy and look fantastic on shelves. They create a stand on their own. Thus, it is easy for the customers to find them. Search more about flexible coffee pouches.

Flat Bottom Bags (Box Pouch): These bags are square in shape when expanded. Very sturdy five sided form that can be printed on. That means you can share the story of your brand even more.

Side Gusset Bags: This style is common in coffee shops. They take up less space packing all that coffee and are easy to fill.

Quad Seal Bags: These bags are also the same as side gusset bags except they have four seals located on each corner of the bag. This makes it look more neat and also helps maintain the shape.

Key Features for Freshness and Ease

Subtle features can affect a customer's perception of your product significantly.

One-Way Degassing Valves: This is vital to freshly roasted coffee. Coffee beans are after gas during roasting. This valve allows gas to escape but doesn’t allow bad oxygen to enter. So the coffee remains fresh.

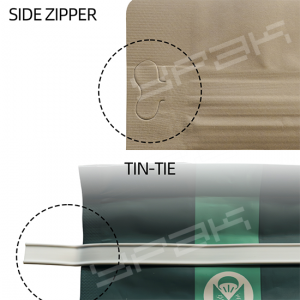

Resealable Zippers or Tin Ties: These closures let customers reclose the bags and easily open them again after purchase. They help maintain the freshness (if you can call it that) and are easy to use.

Tear Notches: The tear notches are the small pre-cut marks at the top that help customers to open the bag easily without using scissors.The tear notch is an easy way for users to remove the tab from the bag, making it easy to open the bag, without the need for scissors.

Hang Holes:A top hole makes it easy for display Hook Hanging in the store.

The 7-Step Custom Coffee Bag Process: From Idea to Your Door

Ordering personalized bags can seem complicated. We've broken it down into seven simple steps to help you keep an eye on your project and trust and work seamlessly with suppliers.

Step 1: Define What You Need & Your Budget Be sure you know what kind of car you want beforehand. You must choose the size of the bag (e.g.: Repeat 12 oz 1 lb…) How Many Bags And what features you want (valves, zippers…). Decide what your target cost per bag will be to help influence your choices.

Step 2: Pick a Packaging Partner Look for a partner that’s a good fit for your unique needs. Ask for a sample of what their stock bags come with so you can asses the quality. Make sure you check their minimum order quantity to be able to match yours.

Step 3: Finish Your Design & Artwork Your Design Your supplier will offer you a design template. Feel free to use that template to make your own design. Most suppliers will need a vector file such as. AI or good PDFs for best printing.

Step 4: The Digital Proof Stage The process begins with getting the proof. Here's a flat version of your end-result design. Clients also have a tendency to rush through this step and complain about it latter. Each of these is looking for something, all that details, please! Double check your colors, word spellings, and test that bar-code to make sure it all works. Also, ensure your legal information, such as the net weight, is correct and included.

Step 5: Production & Printing Once you approve the proof we enter the production phase. The primary print processes are digital and rotogravure. Digital is great for smaller orders, rotogravure helps us best at large bulk orders and is the less expensive per bag.

Step 6: Quality Control & Finishing local quality assurance, auditing, packing and shipping is done After printing pack can be made. This is where zippers, spouts, and tear notches are applied. The supplier performs quality checks to verify that all the specs are met.

Step 7: Shipping & Logistics Your bag is finished and it is time for packing and shipping. Be aware of the lag times. The sea freight is more economical but it is time-consuming. Air freight is quicker but it costs considerably more. This step is the heart of your journey in making your best coffee bags.

Designing Great Custom Coffee Bags To Boost Sales

Your bag design is an invisible salesman. It needs to grab your customers attention and persuade them why they should buy your coffee. A custom coffee bag, designed well can be the factor.

Telling Your Brand Story

Your design should serve as the mirror that reflects what is special about your brand. Do you coffee exclusively from that one extraordinary farm? Is it ethical in sourcing? Does it taste very pungent? Tell it on your package using images, colors and words.

Parts of a Great Coffee Bag Design

A great design moves the customer's eye instinctively.

• Visual Order: Arrange the most important information in such a way as to be seen first. A common order is Logo -> Coffee Name -> Tasting Notes.

• Color Psychology: Colors are the silent language of feeling. Naturally, earthy shades such as browns and greens can suggest naturalness or eco-friendliness. Bright, cheerful colors can complement a modern and energetic brand image.

• Typography: Fonts you choose reflect your brand personality. A straight typeface: You’re modern. Use a script font for an elegant or traditional aesthetic.

Info That's Required vs. Recommended

Some require the bag's main contents by the law, while others are kudos for customer reference.

• Required: The weight of the coffee and the name of your brand/company address.

• Highly Recommended:Roast level (Light, Medium, Dark), tasting notes, coffee origin, roast date, and brewing tips.

An increasing number of brands are featuring their values through the packaging. As seen with options available on platforms like noissue, showing green information has become one of the key parts count in the design of the coffee bag.

Avoiding Common Problems: 5 Costly Mistakes in Custom Bag Orders

We have helped countless people along the way. Along the way, we’ve encountered some mistakes that, if avoided, save both time and money. By cribbing from them, you can make your project go much more smoothly.

Mistake 1: Ignoring Minimum Order AmountsCustom printing has very high setup costs, that’s why suppliers have minimums - anywhere from 1,000 to 5,000 bags is typical. Trying to order less than a supplier’s minimum “can kill a project before it even starts.”

Mistake 2: Sending Low-Quality Artwork “Garbage in garbage out” There’s a simple rule in printing: craps in = craps out. If the logo or image is dark, the print will look even worse. Make sure to always include vector files (. AI,. EPS) for your artwork.

Mistake 3: Picking the Wrong Material for Your Shelf-Life GoalsA bag is only as gorgeous as the space it fills when in use: no amount of (elegant) leather is going to do the trick if it’s leaking air — or moisture from the coffee. If your coffee will need to remain fresh for a long time, you’ll want to choose packaging with a very good barrier, such as aluminum foil.

Mistake 4: Not Planning for Lead Times Getting custom coffee bags isn’t easy. The typical process takes approximately 6-10 weeks from final design approval to having the bags in your hands. Make those plans now, so you don't run out of stuff.

Mistake 5: Forgetting the "Unboxing" Experience A lot of brands concentrate strictly on the front of the bag alone. However, the customer experience also includes the touch of the fabric, the crisp sound made by the zipper, and how effortlessly it can be opened. Those unnoticeable details do a lot to create a premium brand feel. If you take a look at the assortment of custom-printed coffee bag packaging options that are there, you will be able to imagine your final product much better while also avoiding design mistakes.

Conclusion: Elevate Your Brand with the Perfect Package

So, learn on the pathway to building a perfect package. Create a powerful tool for your brand Through the right materials, features, and simple process, your design will tell your story, alongside you telling your story.

Just always remember that your customized coffee bags are not mere bags. They are your first impression, the one who sits next to your brand on the market, and part of the clients’ experience. Use what you read in this guide to bridge the disconnect between your vision and someone who can make it into packaging.

FAQ: Your Custom Coffee Bag Questions Answered

Minimum quantities are very different from suppliers and printing types to printing types. Fo r top of the line (high or 5 colour ) rotogravure printing minimums from 5000-10 000 bags p er design are what to expect. Digital printing, however, has allowed me to order lower quantities. Now some suppliers will offer minimums as low as 500 or 1,000 bags but the cost-per-bag will be higher.

Be ready to receive it between 6-12 weeks. This generally includes 1-2 weeks for design and approval of proofs, 4-6 weeks to produce and 2-4 weeks to ship via ocean. It is faster but also much more expensive to air ship.

Yes, any quality supplier will use a food grade materials and inks. The inside of the bag is always some kind of a food-safe plastic, just like LLDPE. This is a safe layer for your coffee to have between any other materials or inks. Be sure to review this with your packaging partner of choice.

Most providers will post you free generic samples. This allows you to feel the fabric and view the contour or shape of the bag. It’s typically not feasible (or is very expensive, often $500+) to receive a single “prototype” of your exact design due to the substantial setup costs for printing. The digital proof is the typical method to approve your design.

Rotogravure printing does use engraved metal cylinders. For very large orders (over 10,000), it produces the highest print quality and the lowest cost per bag. However, it does have high initial setup fees. Digital printing, on the other hand, works like a very advanced printer, where ink is directly being applied to the material. It's perfect for small orders (from 500 to 5,000 bags) and allows for more flexibility in design.

Post time: Oct-30-2025