The Ultimate Guide to Choosing a Coffee Packaging Manufacturer

Your Packaging Is Your Silent Salesperson

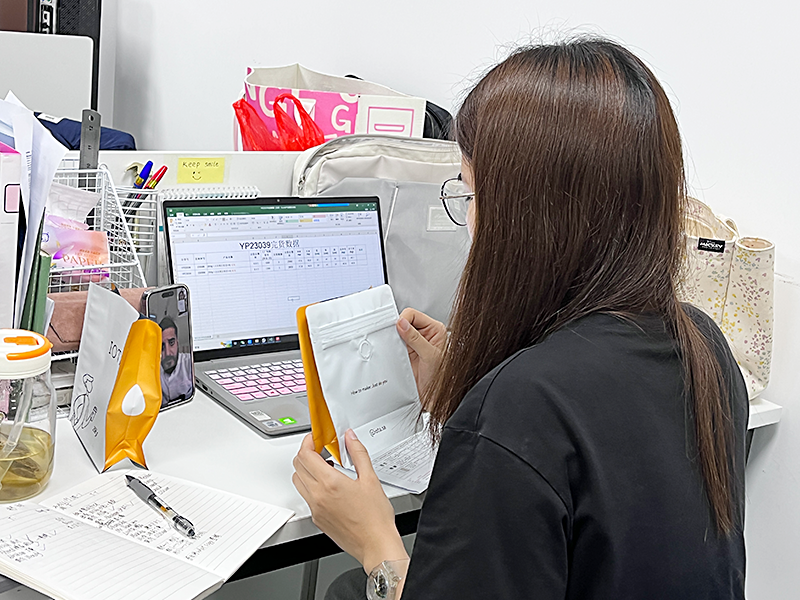

The package is as important as the beans themselves for each coffee brand. It is the first thing they slap their eyes on in a crowded shelf. Packaging : The layer of protection You might have been warned, Quality packaging keeps your coffee fresh itself and narrates the story about your brand. It's your silent salesperson.

With this guide, you will have a good course of action for selecting the best coffee packaging manufacturer. Here to help break it down for you.

But you will learn how to judge a partner. You will learn how the process goes in detail. You will know what to ask. We have years of experience. We know what it means to be a manufacturer's partner. A good partner helps you win with your brand.

Beyond the Bag: A Key Business Choice

Choosing a Coffee Packaging Manufacturer Goes Beyond Buying Bags This one a massive business decision that impacts EVERYTHING on your brand. And this decision will be evident in your long-term success.

It is what keeps your brand to be looking the same all over. The color, logo, and quality of your product always remains the same on every package. This builds trust with customers. For example, research demonstrates that package design can influence a buyer's decision. This makes consistency vital.

The right materials keep your coffee fresh. Special films and valves protect the flavor and smell of your beans. A responsible coffee packaging manufacturer is also safeguarding your supply chain. They lead to delays that could damage your sales.

You will develop with the right partner. They process your first test order. And they manage your future large orders as well. For a coffee brand that is growing this self replicating signal of growth is crucial.

Core Skills: What to Expect from Your Coffee Packaging Manufacturer

Key competencies one needs from a coffee packaging maker Or they do this to ‘size’ each company they evaluate.

Material Know-How and Options

Your Manufacturer ought to understand variation of material They should offer many choices. This includes old-style and green options. Knowing about multilayer laminate structures shows they know their stuff.

- Standard Films: Standard films are multiple plastic layers like PET, PE, and VMPET. Others would go for aluminum since it offers the best air and light protection.

- Green Options: Inquire about available sustainable materials Inquire About Bags Made With Recycled Content Inquire Regarding Compostable Products, Including P.L.A.

Printing Technology

How your bag looks and how much it costsThe method of printing A good manufacturer willpresentoffer to provide you options that best fit your needs.

- •Digital Printing: Works well for short runs or orders which carry innumerable designs. There are no plate fees. Images quality- This printer produce high resolution prints.

- •Rotogravure Printing: it uses metal cylinders that are engraved. Really only for massive amounts of an asset. Nice quality, cost per bag is very low. There are, however, set-up costs involved in the cylinders.

Bag and Pouch Types

The shape of your coffee bag determines how it sits on shelves. It also impacts the way customers are able to utilise it.

- •Common types include Stand-Up Pouches, Flat Bottom Bags, and Side Gusset Bags.

- •Check out our full range of versatile coffee pouches to see these types in action.

Custom Features

The quality and freshness measures do have impact from relatively minor features in terms of user experience.

- •One-way valves: Let CO2 out without letting air in.

- •Zip closures or tin ties: Keep coffee fresh after opening.

- •Tear notches: For easy opening.

- •Special finishes: Like matte, gloss, or soft-touch feel.

Certifications and Rules

The burden is on your manufacturer to prove that their products are safe. They have to provide what they say is correct.

- •Look for food-safe certifications like BRC or SQF.

If you pick green options, ask for proof of their certifications.

The 5-Step Process: From Your Idea to Final Product

Finding the coffee packaging manufacturer requested is tough. More brand launches their packaging through us Find out what I did with this 5-step easy plan.

- 1.First Talk and Quote This was the first conversation. You'll discuss your vision. You will discuss the number of bags you require and your budget. A manufacturer needs to know your bag size, material, features and artwork in order to provide you a good quote.

- 2.Design and Template Once you agree on the plan, the manufacturer gives you a template. A template is a 2D outline of your bag. This is what your designer uses to align your artwork properly. You then submit the final art file. That would be a PDF or Adobe file.

- 3.Sample and Approval This is the most crucial step. You receive a preproduction sample of your bag. It could be digital or physical. From colors, to text, logos and placement you need to check everything. After you approve the sample, production will begin.

- 4.Production and Quality Check This is where your bags are made. The process involves film printing This comprises one of joining layers as reinforcement. They also cut and shape material for bags. Today, manufacturers who control quality check it at each step.

Shipping and Delivery Your order is packed after a Quality Assurance process and it is shipped. Know Your Lead Times This is the time from when you approve the sample to delivery. The right partner will guide you through creating perfect coffee bags from start to finish.

The Check List: 10 Key Questions to Ask

If you are considering a coffee packaging manufacturer, ants in your pants. You may also get potential partners from your industry contacts. You can also check reputable supplier directories like Thomasnet. Use this list to interview them.

- 1.What are your Minimum Order Quantities (MOQs)?

- 2.Can you explain all setup costs like plate fees or design help?

- 3.What is your typical lead time from final sample approval to shipping?

- 4.Can you provide samples of bags you've made with similar materials and features?

- 5.What food-safe certifications do you hold?

- 6.How do you handle color matching and ensure print quality?

- 7.Who will be my main contact through this process?

- 8.What are your options for green or recyclable packaging?

- 9.Can you share a case study or reference from a coffee brand like mine?

- 10.How do you manage shipping, especially for international clients?

Conclusion: Choosing a Partner, Not Just a Supplier

Choosing a Coffee Packaging Manufacturer- Important for Your Brand It is all about finding a partner who gives a damn about your success. This partner should be able to grasp your vision and product.

A good manufacturer will bring you expertise, consistency, and consistent quality to your enterprise. The Give your coffee gravity and the Shelf Life extension? A quality partner can ensure that your packaging makes you proud.

At YPAK COFFEE POUCH, we pride ourselves on being that partner for coffee brands around the world.

Frequently Asked Questions (FAQ)

Q1: What's the difference between digital and rotogravure printing for coffee bags?

A: In simple words, digital printing is nothing but an ultra-advantageous desktop printer. Ideal for smaller orders (generally less than 5,000 bags) or projects with numerous designs. It does not include additional plate fees for use. Rotogravure printing gathers its inks from large, carved metal cylinders on long presses. It gives incredible quality at very competitive cost per bag rates on massive runs. However, the cylinders are not included when you pay the amount.

Q2: How important is a valve on a coffee bag?

A: Beans give off carbon dioxide (CO2) gas after roasting. The gas accumulates, transforming into pressure that causes the bag to explode. A single way valve to let out the CO2 and not let air it, as air makes coffee stale. The valve is therefore vital when it comes to maintaining the freshness of your coffee.

Q3: What does MOQ mean and why do manufacturers have them?

A: MOQ means Minimum Order Quantity It is the minimum number of bags you can have made for a custom run. A minimum order quantity makes some kind of sense since it costs money to set up the giant printing and bag-making machines that a coffee packaging manufacturer works with. For the manufacturer, MOQs keep each production job economically viable.

Q4: Can I get fully compostable coffee packaging?

A: Correct me if I am wrong, but this is also happening. Today, numerous manufacturers provide bags made of plant-based materials, such as PLA or special kraft paper. You can also receive compostable valves and zippers. Make sure you ask your manufacturer for the remaining certifications. Also, question about the conditions under which compost is necessary. Others require manufacturing facilities or something as opposed to a home compost bin.

Q5: How do I ensure the colors on my bag match my brand's colors?

A: Provide your brand Pantone (PMS) color codes to your manufacturer. Do not trust the colors you see on your computer screen (those are RGB or CMYK). These can vary. Your PMS codes will be used by any good manufacturing to match the ink colors. They will provide a final sample for your approval before printing your full order of custom printed coffee bags and pouches.

Post time: Aug-13-2025